Views: 0 Author: Site Editor Publish Time: 2026-01-06 Origin: Site

In professional door hardware specification, cycle testing is one of the most misunderstood performance indicators.

While many products are labeled “heavy duty,” only standardized cycle testing can objectively demonstrate how long hardware will perform reliably in real buildings.

A claim such as “200,000 cycles tested” is not a marketing statement — it represents controlled mechanical endurance testing under European and international standards, directly linked to service life, maintenance cost, and project risk.

•What cycle testing actually measures

•Why 200,000 cycles matters in commercial projects

•How different EN standards define cycle requirements

•How cycle performance integrates with fire testing and corrosion resistance

•What B2B buyers should evaluate beyond the number itself

Cycle testing simulates repeated real-world operation of door hardware under controlled conditions.

A single cycle typically includes:

•Opening the door to a defined angle

•Closing and latching the door

•Applying standardized force and speed

Tests are conducted using automated test rigs, ensuring consistency and repeatability.

•200,000 cycles ≈ 20–25 years of use in high-traffic commercial buildings

Office buildings

Hotels

Hospitals

Schools

Fire-rated stairwells

This level of testing corresponds to severe-duty classifications under multiple EN standards.

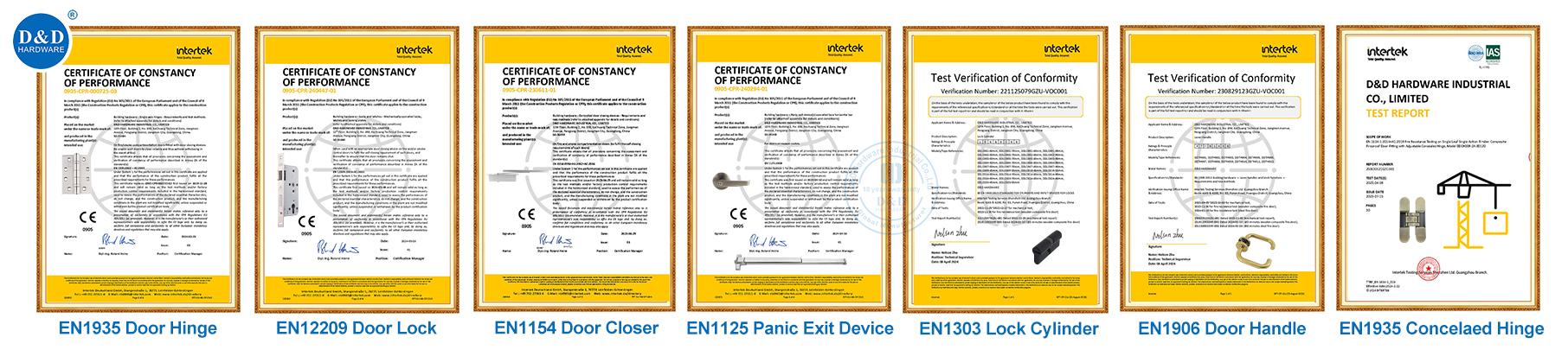

Different hardware categories are governed by different EN standards, each defining minimum cycle requirements.

•High-performance hinges are tested to 200,000 cycles (Grade 7 durability)

•Applicable to both:

Surface-mounted hinges

Concealed hinges

•BS EN 1935

•200,000 cycles tested

•Fire rated up to 192 / 260 minutes

•Corrosion resistance up to EN 1670 Grade 4 (240 hours)

•BS EN 1935

•200,000 cycles tested

•EN 1634 fire rated 132 minutes

•EN 1670 corrosion resistance 48 hours

•High-grade mortise locks require 200,000 operating cycles

•Testing includes:

Latch operation

Deadbolt engagement

Combined load conditions

•BS EN 12209

•200,000 cycles tested

•Fire rated up to 111 / 260 minutes

•EN 1670 corrosion resistance 240 hours

Door closers face some of the most demanding cycle requirements.

•BS EN 1154

•500,000 cycles tested

•Fire rated 120 / 180 minutes

•EN 1670 corrosion resistance 96 hours

•BS EN 1906

•300,000 cycles tested

•Fire rated up to 183 / 260 minutes

•EN 1670 corrosion resistance 240 hours

Return spring fatigue

Spindle deformation

Fixing system stability

•BS EN 1303

•100,000 cycles tested

•Fire rated 183 minutes

•EN 1670 corrosion resistance 96 hours

Cylinder cycles simulate key insertion and rotation, directly impacting security reliability.

•BS EN 1125

•200,000 cycles tested

•Fire rated 132 / 240 minutes

•EN 1670 corrosion resistance 240 hours

Cycle durability must be evaluated together with fire resistance and corrosion performance.

•But fail early due to corrosion

•Or deform under fire exposure

•High-cycle durability

•EN 1634 fire testing

•EN 1670 corrosion resistance

This triad of performance defines true commercial-grade hardware.

•Cycle durability is addressed through ANSI/BHMA grades

•Fire endurance is validated by UL 10C

•Hinges: ANSI/BHMA Grade 1 & 2, UL 10C fire rated 3 hours

•Locks, closers, exit hardware: UL 10C 3 hours

•Panic hardware: UL 305 listed

•Mechanical durability

•Fire performance under positive pressure

•AHJ acceptance

In modern commercial and fire-rated buildings, 200,000 cycles is not an extra — it is a baseline requirement.

True performance is achieved when:

•Cycle testing

•Fire resistance

•Corrosion resistance

are engineered and certified together.

With its CE-certified EN hardware range and UL-listed fire-rated hardware, D&D provides verified, system-level durability that meets the expectations of engineers, QC teams, and professional buyers worldwide.

Contact us Now:

Contact: David Jian

Mob:0086-139 2903 7292

Email: David@dndhardware.com, sales@dndhardware.com,

Jobby Zhang

Mob:0086-137 2599 9617

Email: jobby@dndhardware.com

D&D HARDWARE INDUSTRIAL CO.,LTD

ADD:12th Floor, Building 2, No.898, KeChuang Technical Zone, Jiangmen Avenue, Pengjiang District, Jiangmen City, Guangdong, China (Postcode:529000)

https://www.dndhardware.com

Tel: +86-750-3856396

Fax: +86-750-3856395