Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

Fire-rated door systems are a critical element of passive fire protection in commercial and public buildings. While much attention is often given to the fire rating of the door leaf itself, door hardware plays an equally vital role in ensuring fire performance. EN 1634 fire testing is the primary European standard used to evaluate how doors and their hardware perform under real fire conditions.

This article provides a clear, technical explanation of what EN 1634 fire testing is, how it applies to door hardware, and why understanding EN 1634 results is essential for compliant commercial projects and informed specification decisions.

EN 1634 is a European test standard used to determine the fire resistance performance of door and shutter assemblies. It evaluates how long a door system can maintain its fire-separating function when exposed to fire under controlled laboratory conditions.

EN 1634 is divided into several parts, with EN 1634-1 being the most commonly referenced for fire doors and door hardware.

EN 1634-1 focuses on:

*Fire resistance of doors, shutters, and openable windows

*Performance under standard fire exposure curves

*Integrity and insulation (depending on classification)

For door hardware, EN 1634 testing confirms whether hinges, concealed hinges, locks, closers, handles, cylinders, and panic devices can remain functional and structurally stable during a fire.

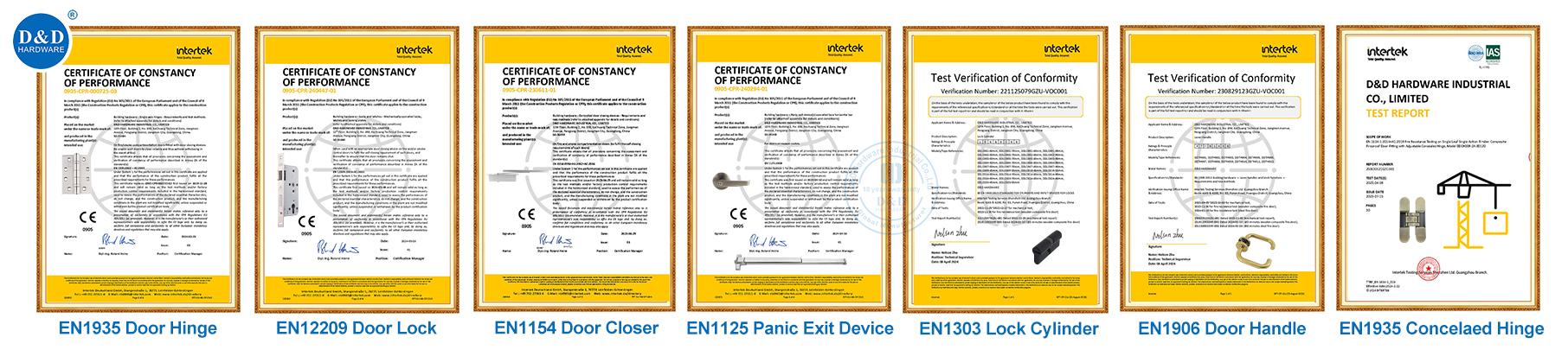

✔️ Door Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 192mins/260mins, EN1670 Corrosion Resistance 240 hours.

✔️ Concealed Hinge-BS EN1935 200,000 cycles test, EN1634 Fire Rated 132mins, EN1670 Corrosion Resistance 48 hours.

✔️ Door Lock-BS EN12209 200,000 cycles test, EN1634 Fire Rated 111mins/260mins, EN1670 Corrosion Resistance 240 hours.

✔️ Door Closer-BS EN1154 500,000 cycles test, EN1634 Fire Rated 120/180mins, EN1670 Corrosion Resistance 96 hours.

✔️ Door Handle-BS EN1906 300,000 cycles test, EN1634 Fire Rated 183/260mins, EN1670 Corrosion Resistance 240 hours.

✔️ Lock Cylinder-BS EN1303 100,000 cycles test, EN1634 Fire Rated 183mins, EN1670 Corrosion Resistance 96 hours.

✔️ Panic Exit Device-BS EN1125 200,000 cycles test, EN1634 Fire Rated 132/240mins, EN1670 Corrosion Resistance 240 hours.

A fire-rated door is only effective if it closes, stays closed, and maintains compartmentation during a fire. Door hardware directly affects all three of these functions.

If door hardware fails:

*The door may not close properly

*Gaps may form due to deformation

*Fire and smoke can spread prematurely

*Safe evacuation routes may be compromised

EN 1634 fire testing ensures that door hardware does not become the weak link in the fire door system.

EN 1634 fire testing is performed on full-size door assemblies, not on individual components in isolation.

*Door leaf and frame

*Hinges

*Lock and locking points

*Door closer

*Handles, cylinders, and exit hardware

The assembled door is mounted in a furnace and exposed to a standard time–temperature fire curve, simulating real fire conditions.

*Structural integrity of the assembly

*Deformation of hardware components

*Whether the door remains closed

*Continued operability where required for egress

The test continues until failure criteria are met or the maximum test duration is reached.

EN 1634 test results are expressed in minutes, such as:

*60 minutes

*90 minutes

*120 minutes

*180 minutes

*260 minutes or more

When door hardware is described as “EN 1634 fire rated 120 minutes,” it means that the hardware successfully supported the door system’s fire resistance for at least that duration under test conditions.

Different hardware types may achieve different fire resistance durations, depending on their function, materials, and installation position.

EN 1634 fire testing is a key requirement for CE marking of fire-rated door hardware under the Construction Products Regulation (CPR).

For CE certification, manufacturers must demonstrate:

*Successful EN 1634 fire test results

*Compliance with the relevant EN product standard

*Mechanical durability through cycle testing

*Corrosion resistance under EN 1670

*Factory Production Control (FPC)

Only hardware that meets all applicable requirements can be CE marked for fire-rated door applications.

One common misunderstanding is that EN 1634 only evaluates fire exposure. In reality, it also indirectly tests system behavior under stress, including:

*Door leaf distortion and frame movement

*Increased load on hinges and closers

*Lock and latch engagement under deformation

*Continued usability of panic and exit hardware

This is why EN 1634 results are so critical for commercial buildings with high occupancy and strict life-safety requirements.

For engineers, architects, and specification consultants, understanding EN 1634 helps to:

*Verify whether door hardware is suitable for fire-rated doors

*Avoid mixing certified and non-certified components

*Ensure compliance with local fire codes and EN-based regulations

*Reduce inspection failures and project delays

In many cases, fire inspectors will request EN 1634 test evidence or CE documentation during approval stages.

*High traffic frequency

*Long service life expectations

*Emergency operation requirements

*High cycle durability testing (e.g. EN 1935, EN 1154, EN 1906)

*Corrosion resistance classification (EN 1670)

This ensures that hardware performs not only in a fire, but also throughout years of daily use.

From a project risk perspective, using door hardware with verified EN 1634 fire test results provides:

*Confidence during fire inspections

*Clear documentation for compliance submissions

*Reduced liability in post-incident investigations

*Lower long-term maintenance and replacement risk

Non-tested or non-certified hardware may appear similar in appearance, but cannot provide the same level of documented fire performance.

For projects that require both regulatory compliance and long-term reliability, selecting door hardware that has been:

*Tested under EN 1634

*Certified to relevant EN standards

*Designed for commercial fire door systems

is a practical and responsible engineering decision.

Manufacturers with comprehensive EN-certified product ranges are better positioned to support complete fire door solutions, documentation needs, and cross-product compatibility.

EN 1634 fire testing is the foundation of fire-rated door hardware compliance in EN-based markets. It verifies that door hardware can withstand real fire conditions and support the fire door system in maintaining compartmentation, integrity, and safe egress.

For commercial projects, understanding EN 1634 is not just about meeting a standard—it is about making informed, risk-aware decisions that protect lives, property, and project outcomes.

Contact us Now:

Contact: David Jian

Mob:0086-139 2903 7292

Email: David@dndhardware.com, sales@dndhardware.com,

Jobby Zhang

Mob:0086-137 2599 9617

Email: jobby@dndhardware.com

D&D HARDWARE INDUSTRIAL CO.,LTD

ADD:12th Floor, Building 2, No.898, KeChuang Technical Zone, Jiangmen Avenue, Pengjiang District, Jiangmen City, Guangdong, China (Postcode:529000)

https://www.dndhardware.com

Tel: +86-750-3856396

Fax: +86-750-3856395