Views: 814 Author: D&D Door Hardware Publish Time: 2016-07-01 Origin: D&D

The D&D Hardware rang of architectural lock is manufactured to the highest engineering standards and designed to offer a high price/performance ratio. They have been successfully type tested to all the requirement of BS EN 12209.

Features & Functions

D&D Hardware architectural range of Locks and latches designed to support the entire D&D Hardware range of levers, knobs and other unsprung furniture.The range is suitable for general commercial and heavy industrial use.

Offering complementary build quality, design integrity, and choice of external finishes, D&D Hardware gurantees the perfect match between form and function whenever you specify D&D Hardware architectural ironmongery. With fire safety and security in mind, D&D Hardware have design this series. Solid stainless steel latchbolts, deadbolts, followers, forend and strike plates provide enhanced durability and security.

Rebate conversion are available to allow locks to be fitted in most rebated door sections.

1.Stainless steel forend and strike plate .

2.Reversible latchbolt.

3.Solid stainless steel latchbolt

4.Stainless steel spindle follower.

5.Flush fitting case rivets and screws.

6.Solid stainless steel deadbolt .

Guarantee

D&D Hardware mortice locks are supplied with a 10 year guarantee.See each individual product page for details.

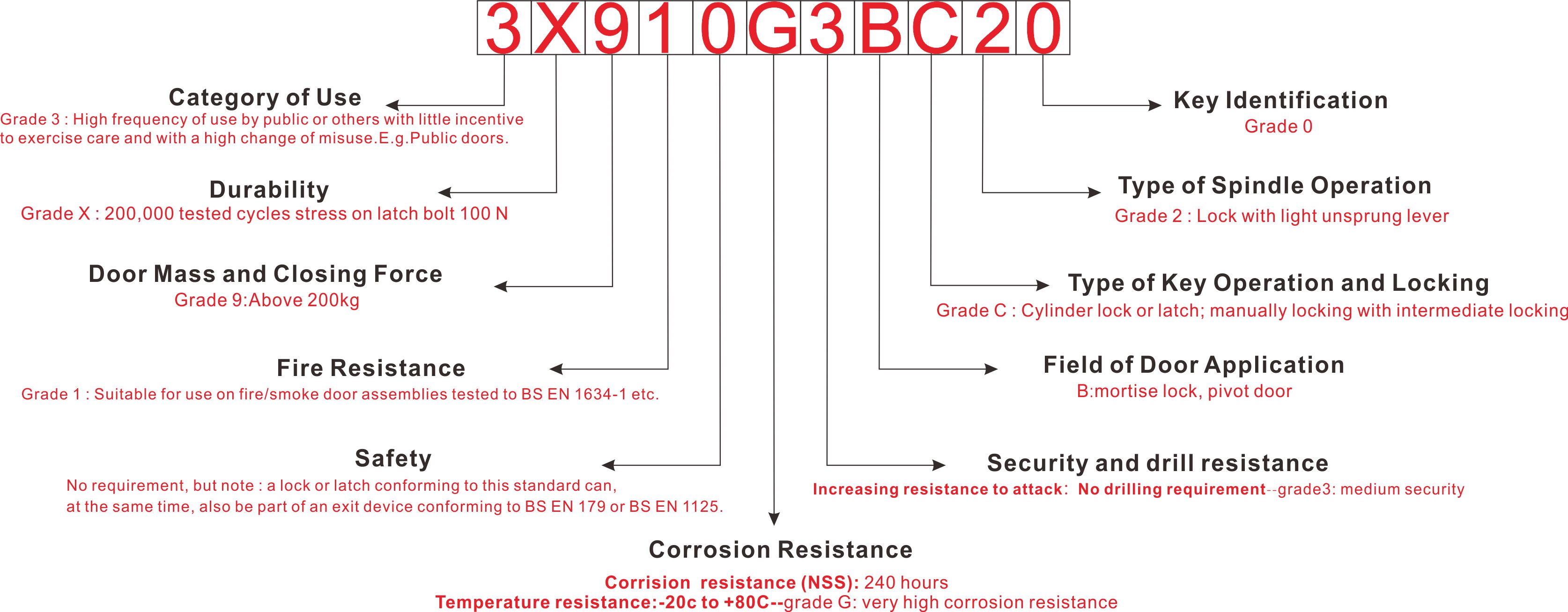

EN 12209 classifies mechanically operated locks, latches and locking plates using an 11 digit coding system. Fundamental to this standard is a comprehensive classification system for assessing the wide range of products needed to satisfy the diverse requirements of the European market.

Features assessed include normal use (and abuse) forces, long-term durability, fire/smoke resistance, corrosion and temperature resistance and security, both manipulative and physical.

1.Category of use

Three grades are identified:

Grade 1 : Low frequency of use by people with a high incentive to exercise care and a small chance of misuse.E.g.Internal residential doors

Grade 2 : Medium frequency of use by people with some incentive to exercise care but where there is some chance of misuse.E.g.Internal office doors.

Grade 3 : High frequency of use by public or others with little incentive to exercise care and with a high change of misuse.E.g.Public doors.

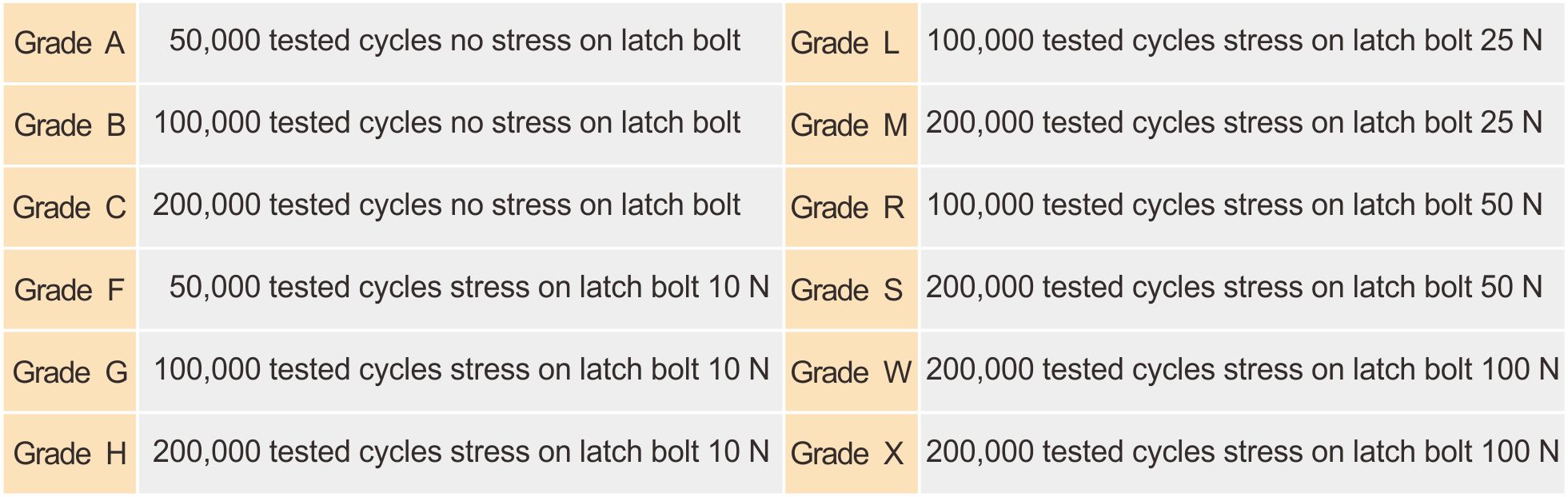

2.Durability

Twelve grades are identified with minimum figures for deadbolt and snib operation, and latch bolt operation with and without side load, as show. The side load is applied to the latch bolt when it is being withdrawn.

3.Door mass and Closing Force

Nine grades are identified with maximum figure for closing force at various door masses as shown. Note :losing force is form a standing. Star :i.e.fully extended latch bolt in contact with striking plate at star of test .

| Maximun closing | Up to 100kg | Door mass up to 200kg | Above 200kg |

| 15N | grade 7 | grade 8 | grade 9 |

| 25N | grade 4 | grade 5 | grade 6 |

| 50N | grade 1 | grade 2 | grade 3 |

4.Fire resistance

Two grade are identified :

Grade 0 : Not approved for use on fire/smke door assemblies

Grade 1 : Suitable for use on fire/smoke door assemblies tested to BS EN 1634-1 etc.

5.Safety

No requirement, but note : a lock or latch conforming to this standard can, at the same time, also be part of an exit device conforming to BS EN 179 or BS EN 1125.

6.Corrosion resistance

Eight grade are identified with neutral salt-spray (NSS)corrosion resistance grades from BS EN 1670:1988, with and without Temperaturere resistance as shown :

| Corrision resistance (NSS) | Temperature resistance | |

| No requirement | -20c to +80C | |

| 240 hours | grade D:very high corrosion resistance | grade G: very high corrosion resistance |

| 96 hours | grade C:high corrosion resistance | grade F: high corrosion resistance |

| 48 hours | grade B: moderate corrosion resistance | grade E: moderate corrosion resistance |

| 24 hours | grade A: low corrosion resistance | |

| No requirement | grade O: no defined corrosion resistance | |

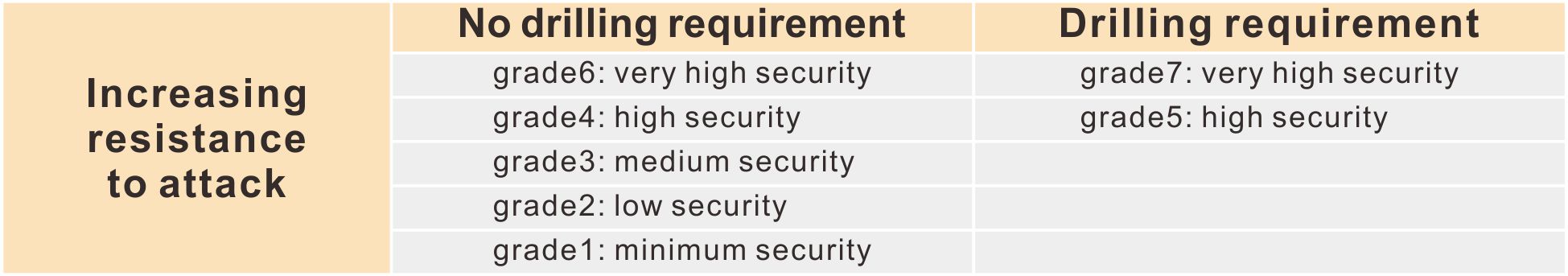

7. Security and drill resistance

Seven grades are identified with minimum figures for requirements relating to physical attack, with or without drilling of the lockcase, as shown:

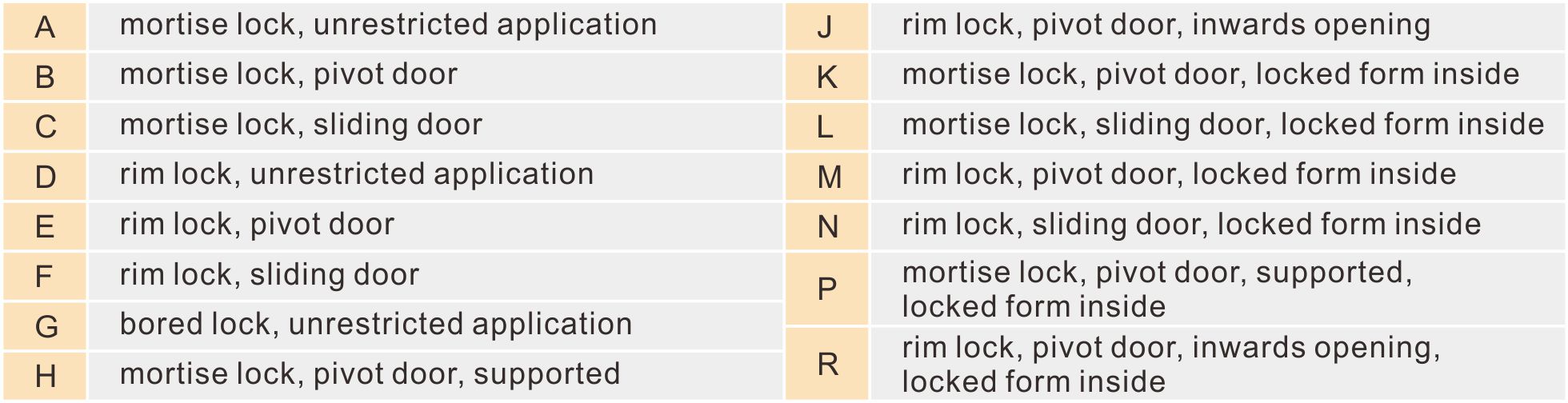

8. Field of door application.

9.Type of Key operation and locking.

Nine grades are identified for differing types of key operation, The grading determines how the lock is assessed foe deadlocking requirement as shown. In addition, there is a maximum key torque operating requirement of 1.5 Nm and a minimum key strength requirement of 2.5 Nm .

Grade 0 : Not applicable;

Grade A : Cylinder lock or latch; manually locking;

Grade B : Cylinder lock or latch; automatically Locking;

Grade C : Cylinder lock or latch; manually locking with intermediate locking;

Grade D : Lever lock or latch; manually locking;

Grade E : Lever lock or latch; automatically locking;

Grade F : Lever lock or latch; manually locking with intermediate locking;

Grade H : Lock or latch without key opreation;manually locking;

Grade G : Lock without key operation; automatically locking.

10. Type of spindle operation

Five grades are identified

Grade 0 : Lock without follower

Grade 1 : Lock with sprung lever or knob

Grade 2 : Lock with light unsprung leverg.

Grade 3 : Lock with heavy unsprung lever

Grade 4 : Lock with manufacturer's own specification furniture

11. Key identification

Nine grades are identified relating to the number of differs and levers.Grades to a latch with no locking action.

| No of differs | No of levers | ||||||||

grade H | |||||||||

grade F | grade G | ||||||||

grade D | grade E | ||||||||

grade B | grade C | ||||||||

grade A | |||||||||

grade 0 | |||||||||

D&D CE mark European Mortise Lock Successfully tested for conformity to all the requirements of BS EN 12209, 11 Classification:3X910G3BC20

BS EN 1634 Part 1: 2000

Is the European Fire Safety Satandard for determining the fire resistance of door and shutter assemblies including hardware designed for installations within openings incorporated in vertical seprating elements (doorsets).

Fire Doors-Locks - EN1634 fire rated 111mins for wooden door, fire rated 260mins for steel door

The UK construction Products Regulations require locks for use on fire doors to be safe and durable. British/European standards BS EN 12209 is the recognised way of demonstrating compliance and requires that an official Notified Body proves both the product and the manufaturer's factory product controls are satisfactory before CE marking can be applied. It is recommended that locks fitted to Fire doors should be CE marked.

CE Marking

CE marking is the easiest and safest route to providing compliance with the latest UK Construction Products Regulations for hardware used on fire, smoke and escape doors.

BS8300 & Approved Document "M" of the Building Regulations

These documents recommend that locks should have a minimum of a 55mm backset and that the centres should be a minimum of a 72mm. Locks with keyways above the cylinder are also suitable.

As a professional door lock manufacturer in China, we provide customers various exterior and interior door lock, like Euro Mortise Lock, CE Door Lock, Deadbolt Lock, Bathroom Door Lock, Narrow Stile Lock, etc. Our door locks are high-quality, durable, anti-rust and textured. The door locks we provide are suitable for wooden door, metal door, fire rated door, double door, single door, steel door of commercial or residential application.

All our products strictly according to international Standard, such as the ANSI, BS EN/CE, UL, BHMA standard.

Contact: David Jian

Mob:0086-139 2903 7292

Email: David@dndhardware.com, sales@dndhardware.com,

Jobby Zhang

Mob:0086-137 2599 9617

Email: jobby@dndhardware.com