DDSS001-FR-4x3.5x3.0mm

D&D Hardware

Wooden Door, Metal Door, Steel Door, Interior Door, Outer Door

UL Listed / UL10C , 3 Hours Fire Rated , NFPA80

Stainless Steel 304 / 316 / 201

SSS , PSS , PVD , PB, AB , AC

T/T, L/C, D/P, Western Union

Jiangmen /Guangzhou / Shenzhen , China

200,000/Month

| Availability: | |

|---|---|

| Quantity: | |

Discover our American Market SS304 Fire-Rated Double Ball Bearing Door Hinge, developed specifically for the North American market – a high-performance UL Door Hinge product bearing UL certification. As a core component of fire door systems, this product is rigorously designed and manufactured to comply with the American UL 10C standard. Having passed authoritative certification, it provides fire doors with up to three hours of fire protection, effectively preventing the spread of flames and smoke. Constructed from SS304 stainless steel, it offers corrosion resistance far exceeding ordinary steel, making it particularly suitable for coastal regions or high-humidity environments. Its core innovation lies in the integrated dual ball bearing structure, significantly reducing friction resistance during door operation. This ensures even heavy fire doors deliver a quiet, smooth opening experience. As manufacturers, we provide not only products but also comprehensive technical support and compliance assurance for B2B clients. This enables your fire door products to effortlessly meet stringent North American building codes, enhancing market competitiveness. Choosing our UL Door Hinge means choosing safety, reliability, and value. For further information, please contact us.

| Product Overview | |

Product Name | American Market SS304 Fire Rated Two Ball Bearing Door Hinge with UL |

| Product Model | DDSS001-FR-4x3.5x3.0mm |

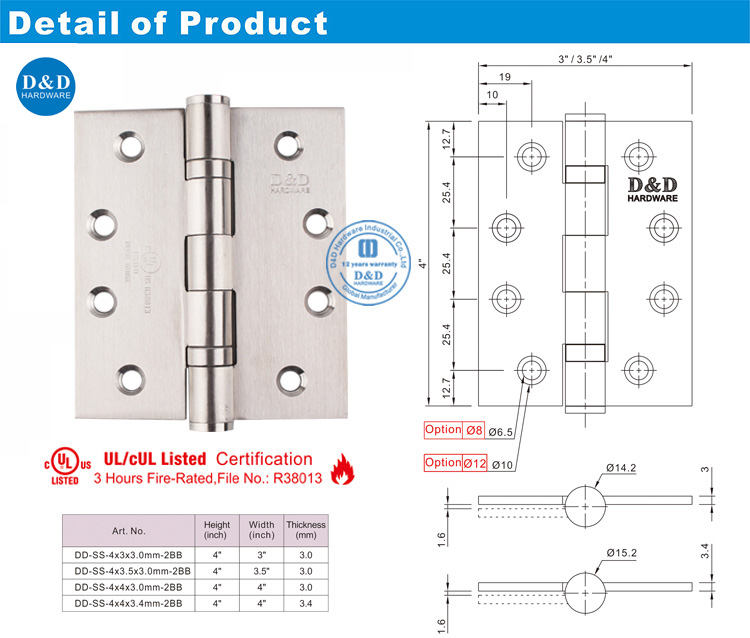

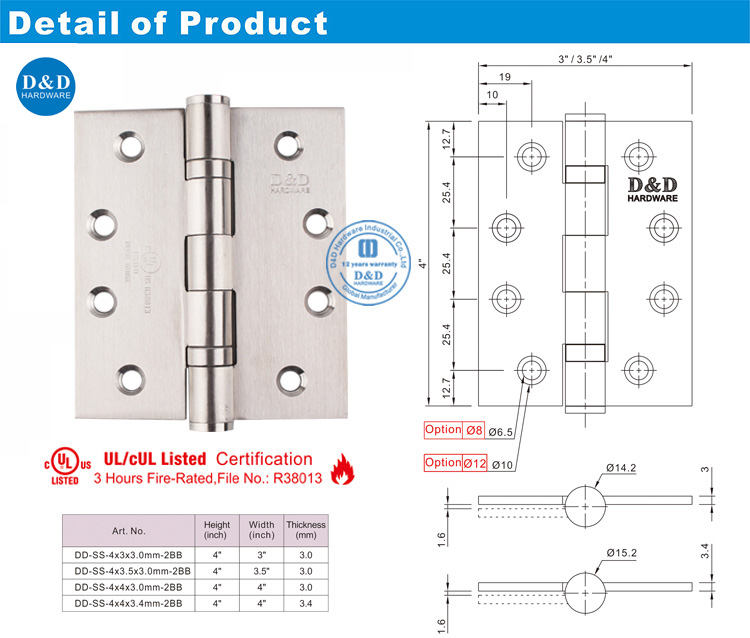

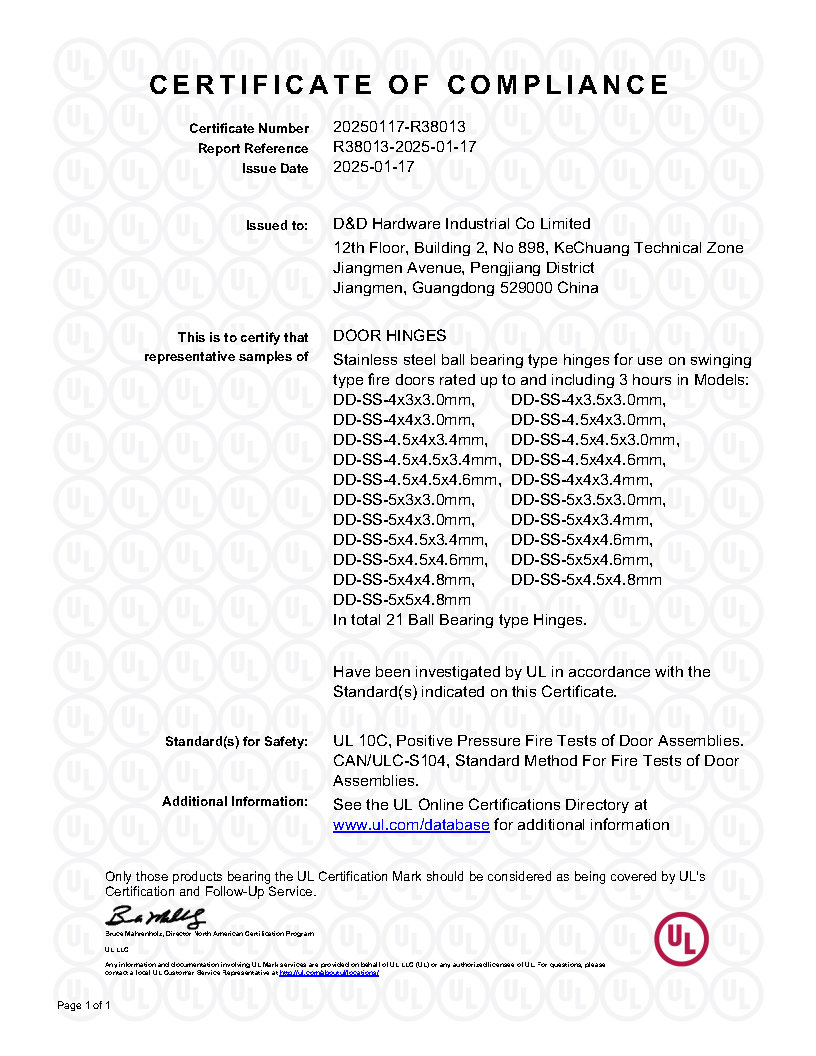

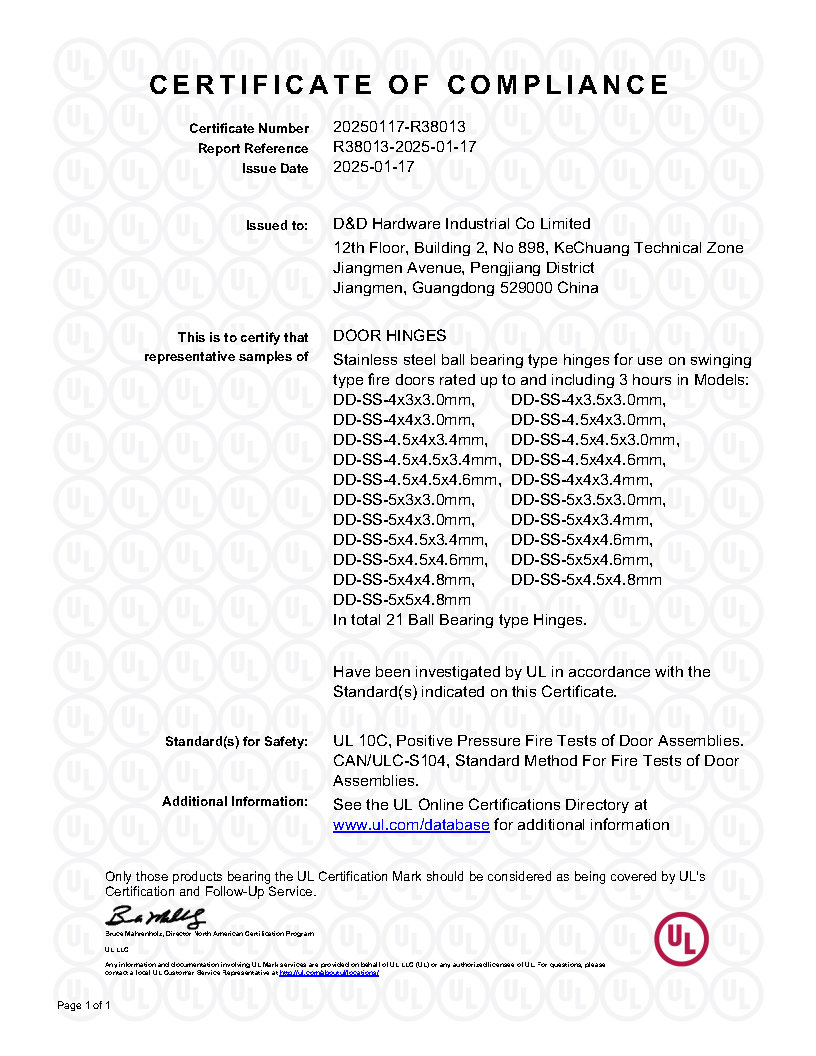

Certification | UL Listed , UL/cUL UL10C , 3 Hours Fire Rated |

UL File Number | R38013 |

Notify Body | UL From U.S.A |

UL certificate item -21 size | 4.0"x3.0"x3.0mm 4.0"x3.5"x3.0mm 4.0"x4.0"x3.0mm 4.5"x4.0"x3.0mm 4.5"x4.5"x3.0mm 4.5"x4.0"x4.6mm 4.5"x4.0"x3.4mm 4.5"x4.5"x3.4mm 4.5"x4.5"x4.6mm 5.0"x4.0"x4.8mm 5.0"x4.5"x4.6mm 5.0"x5.0"x4.6mm |

Material | Stainless Steel 201, 304 or 316 |

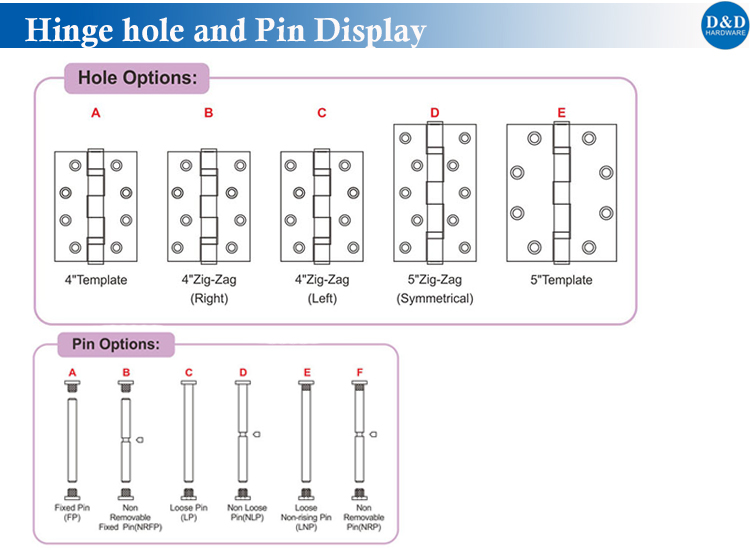

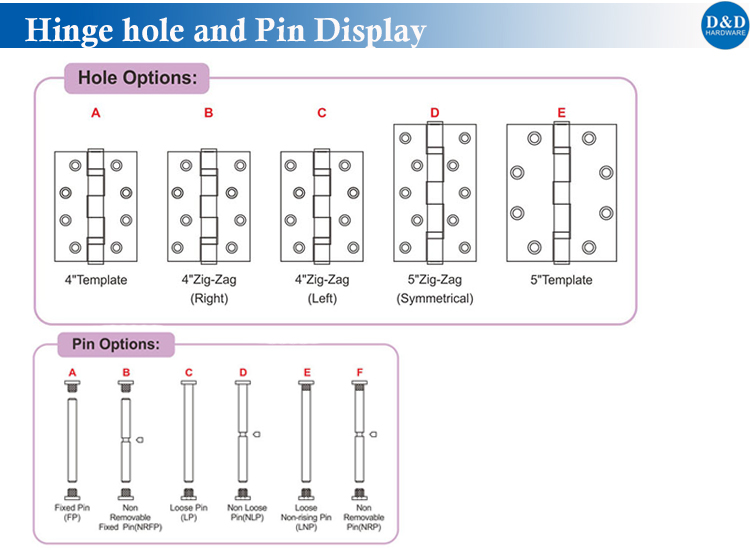

Fitting | Flat tip, ball bearing, fix pin, screws |

Finish | Satin stainless steel, Polished stainless steel, Polished brass, Chrome plated(polish chrome plate&satin chrome plate), Antique brass, Antique copper, Matt black, Physical Vapor Deposition |

Color | Silver,Black, Golden, Antique Brass, Antique Copper etc. |

Suitable for | Wooden door, Metal door, Steel door , Fire rated door |

| Packaging & Shipping | |

| MOQ | 500 Pieces |

| Package | One pair/white box or color box or Blister card in Standard export carton |

| Sample time | 5-7 working days |

| Production lead time | 30-35 days |

| Shipping Port | Jiangmen , China / Shenzhen , China . |

D&D Product

The products that we offer are tested to the most stringent international industry standards, including BS EN, CE, UL, ANSI and BHMA, Suitable for Education, Healthcare, Hospitality, Residential and Commercial applications.

More door hardware items include:

1.Door Hinge- UL 10C R38013 & BHMA/ANSI Grade1/2 & CE EN1935 Grade 13

2.Concealed Hinge- BS EN1935, EN1634 Fire Rated

3.Door Lock - CE EN12209 UKCA Fire Rated & UL 10C R40901

4. Door Handle- BS EN 1906 Grade 4, EN1634 Fire Rated

5. Panic Exit Device- UL 10C R40486 & UL305 SA45817 & CE EN1125

6. Door Closer – CE BS EN 1154 & UL 10C R40717

7. Lock Cylinder-BS EN1303, EN1634 Fire Rated

8. Door Viewer - UL Listed UL 10C Fire Rated R41286

9. Glass Hardware / Bathroom Hardware / Barn Door Hardware

Discover our American Market SS304 Fire-Rated Double Ball Bearing Door Hinge, developed specifically for the North American market – a high-performance UL Door Hinge product bearing UL certification. As a core component of fire door systems, this product is rigorously designed and manufactured to comply with the American UL 10C standard. Having passed authoritative certification, it provides fire doors with up to three hours of fire protection, effectively preventing the spread of flames and smoke. Constructed from SS304 stainless steel, it offers corrosion resistance far exceeding ordinary steel, making it particularly suitable for coastal regions or high-humidity environments. Its core innovation lies in the integrated dual ball bearing structure, significantly reducing friction resistance during door operation. This ensures even heavy fire doors deliver a quiet, smooth opening experience. As manufacturers, we provide not only products but also comprehensive technical support and compliance assurance for B2B clients. This enables your fire door products to effortlessly meet stringent North American building codes, enhancing market competitiveness. Choosing our UL Door Hinge means choosing safety, reliability, and value. For further information, please contact us.

| Product Overview | |

Product Name | American Market SS304 Fire Rated Two Ball Bearing Door Hinge with UL |

| Product Model | DDSS001-FR-4x3.5x3.0mm |

Certification | UL Listed , UL/cUL UL10C , 3 Hours Fire Rated |

UL File Number | R38013 |

Notify Body | UL From U.S.A |

UL certificate item -21 size | 4.0"x3.0"x3.0mm 4.0"x3.5"x3.0mm 4.0"x4.0"x3.0mm 4.5"x4.0"x3.0mm 4.5"x4.5"x3.0mm 4.5"x4.0"x4.6mm 4.5"x4.0"x3.4mm 4.5"x4.5"x3.4mm 4.5"x4.5"x4.6mm 5.0"x4.0"x4.8mm 5.0"x4.5"x4.6mm 5.0"x5.0"x4.6mm |

Material | Stainless Steel 201, 304 or 316 |

Fitting | Flat tip, ball bearing, fix pin, screws |

Finish | Satin stainless steel, Polished stainless steel, Polished brass, Chrome plated(polish chrome plate&satin chrome plate), Antique brass, Antique copper, Matt black, Physical Vapor Deposition |

Color | Silver,Black, Golden, Antique Brass, Antique Copper etc. |

Suitable for | Wooden door, Metal door, Steel door , Fire rated door |

| Packaging & Shipping | |

| MOQ | 500 Pieces |

| Package | One pair/white box or color box or Blister card in Standard export carton |

| Sample time | 5-7 working days |

| Production lead time | 30-35 days |

| Shipping Port | Jiangmen , China / Shenzhen , China . |

D&D Product

The products that we offer are tested to the most stringent international industry standards, including BS EN, CE, UL, ANSI and BHMA, Suitable for Education, Healthcare, Hospitality, Residential and Commercial applications.

More door hardware items include:

1.Door Hinge- UL 10C R38013 & BHMA/ANSI Grade1/2 & CE EN1935 Grade 13

2.Concealed Hinge- BS EN1935, EN1634 Fire Rated

3.Door Lock - CE EN12209 UKCA Fire Rated & UL 10C R40901

4. Door Handle- BS EN 1906 Grade 4, EN1634 Fire Rated

5. Panic Exit Device- UL 10C R40486 & UL305 SA45817 & CE EN1125

6. Door Closer – CE BS EN 1154 & UL 10C R40717

7. Lock Cylinder-BS EN1303, EN1634 Fire Rated

8. Door Viewer - UL Listed UL 10C Fire Rated R41286

9. Glass Hardware / Bathroom Hardware / Barn Door Hardware

1. Certification and fire rating: This product has passed UL/cUL dual certification and meets the requirements of UL 10C standard, with a fire rating of 3 hours. This certification is a necessary condition for the product to enter the North American market, ensuring that your fire door system fully complies with international safety regulations. Each batch of products comes with traceable certification documents, providing buyers with complete compliance proof.

2. Material and process: Made of SS304 stainless steel, this material contains higher nickel and chromium components, and has excellent corrosion resistance and oxidation resistance, with a service life far exceeding that of ordinary 201 stainless steel. The surface has undergone precision mechanical polishing and deburring treatment, presenting a uniform metallic luster that is both aesthetically pleasing and effectively resistant to daily wear and tear.

3. Structure and Size: The product adopts standard dimensions of 4.5 inches by 3.5 inches, with a thickness of 3.5mm to ensure sufficient load-bearing strength. Unique two ball bearing structure design, each bearing is made of high carbon steel material, which has been heat-treated to enhance wear resistance. The hinge pin is designed to be detachable, making it easy to install and adjust the door leaf.

4. Applicable scenarios and supporting facilities: Designed specifically for wooden and steel fire doors, suitable for commercial buildings, hospitals, schools, and other places with high fire safety requirements. It is recommended to use 3-4 hinges per door, and the specific quantity should be determined based on the weight and size of the door leaf. The product provides original stainless steel screws to ensure overall integrity and stability after installation.

1. Innovative design of dual bearings: The core advantage of this UL Door Hing is its unique dual ball bearing structure. Compared with traditional single bearing or bearingless hinges, the dual bearing design can reduce the friction coefficient by more than 70%, making the door leaf opening and closing more lightweight and smooth. Even with long-term use, common problems such as hinge sagging and abnormal noise will not occur, greatly extending the service life of fire doors. This innovative design represents a technological leap in hinge manufacturing, providing buyers with significant product differentiation advantages.

2. Top material guarantee: We insist on using SS304 stainless steel as the raw material, which is in sharp contrast to many products on the market that use carbon steel or low-grade stainless steel. SS304 material not only ensures that the product passes strict salt spray testing (up to 500 hours or more), but also maintains its aesthetic appearance after long-term use. As a manufacturer, we conduct full traceability of raw materials to ensure that every batch of products meets the quality requirements of the North American market. This strict control over materials is our biggest difference from competitors.

1. Preliminary Inspection and Preparation: Upon unpacking, immediately verify the UL certification mark and model identification on the product surface to confirm compliance with your procurement requirements. Count the quantity; typically, each door requires 3-4 UL Door Hinges. Prepare installation tools, including an electric drill, screwdriver, spirit level, and matching installation screws. Check whether the pre-cut dimensions of the door leaf and frame match the hinges, ensuring the installation base is level and secure.

2. Precise Positioning and Marking: Determine hinge placement based on door weight. Typically, the top hinge sits 15-20cm from the door top, the bottom hinge 20-25cm from the door bottom, with the middle hinge centred. Use a spirit level to ensure all mounting points align vertically. Mark drilling positions precisely with a pencil. Accurate positioning directly impacts installation quality and service life.

3. Fitting Hinge Blades: Insert each hinge blade into its respective slot in the door leaf and frame, securing preliminarily with the supplied stainless steel screws. Ensure all hinge bearing holes face the same direction to guarantee correct door swing. Begin fitting from the top hinge and work progressively downward for easier fine-tuning.

4. Door Hanging and Adjustment: Lift the door leaf to align the hinge plates on the door with those on the frame, then insert the hinge pins. Insert the top pin first, followed sequentially by the middle and bottom pins. Verify the door leaf is vertical and operates smoothly. Make fine adjustments by tightening or loosening the adjustment screws as required until optimal performance is achieved.

5. Final Inspection and Testing: Upon completion, conduct comprehensive functional testing. Open and close the door multiple times to check for unusual noises or sticking. Confirm the door remains stable in all positions without self-opening or closing. Finally, verify all screws are securely fastened and advise the user to perform regular inspections and maintenance to ensure this UL Door Hinge consistently delivers optimal performance.

1. Certification and fire rating: This product has passed UL/cUL dual certification and meets the requirements of UL 10C standard, with a fire rating of 3 hours. This certification is a necessary condition for the product to enter the North American market, ensuring that your fire door system fully complies with international safety regulations. Each batch of products comes with traceable certification documents, providing buyers with complete compliance proof.

2. Material and process: Made of SS304 stainless steel, this material contains higher nickel and chromium components, and has excellent corrosion resistance and oxidation resistance, with a service life far exceeding that of ordinary 201 stainless steel. The surface has undergone precision mechanical polishing and deburring treatment, presenting a uniform metallic luster that is both aesthetically pleasing and effectively resistant to daily wear and tear.

3. Structure and Size: The product adopts standard dimensions of 4.5 inches by 3.5 inches, with a thickness of 3.5mm to ensure sufficient load-bearing strength. Unique two ball bearing structure design, each bearing is made of high carbon steel material, which has been heat-treated to enhance wear resistance. The hinge pin is designed to be detachable, making it easy to install and adjust the door leaf.

4. Applicable scenarios and supporting facilities: Designed specifically for wooden and steel fire doors, suitable for commercial buildings, hospitals, schools, and other places with high fire safety requirements. It is recommended to use 3-4 hinges per door, and the specific quantity should be determined based on the weight and size of the door leaf. The product provides original stainless steel screws to ensure overall integrity and stability after installation.

1. Innovative design of dual bearings: The core advantage of this UL Door Hing is its unique dual ball bearing structure. Compared with traditional single bearing or bearingless hinges, the dual bearing design can reduce the friction coefficient by more than 70%, making the door leaf opening and closing more lightweight and smooth. Even with long-term use, common problems such as hinge sagging and abnormal noise will not occur, greatly extending the service life of fire doors. This innovative design represents a technological leap in hinge manufacturing, providing buyers with significant product differentiation advantages.

2. Top material guarantee: We insist on using SS304 stainless steel as the raw material, which is in sharp contrast to many products on the market that use carbon steel or low-grade stainless steel. SS304 material not only ensures that the product passes strict salt spray testing (up to 500 hours or more), but also maintains its aesthetic appearance after long-term use. As a manufacturer, we conduct full traceability of raw materials to ensure that every batch of products meets the quality requirements of the North American market. This strict control over materials is our biggest difference from competitors.

1. Preliminary Inspection and Preparation: Upon unpacking, immediately verify the UL certification mark and model identification on the product surface to confirm compliance with your procurement requirements. Count the quantity; typically, each door requires 3-4 UL Door Hinges. Prepare installation tools, including an electric drill, screwdriver, spirit level, and matching installation screws. Check whether the pre-cut dimensions of the door leaf and frame match the hinges, ensuring the installation base is level and secure.

2. Precise Positioning and Marking: Determine hinge placement based on door weight. Typically, the top hinge sits 15-20cm from the door top, the bottom hinge 20-25cm from the door bottom, with the middle hinge centred. Use a spirit level to ensure all mounting points align vertically. Mark drilling positions precisely with a pencil. Accurate positioning directly impacts installation quality and service life.

3. Fitting Hinge Blades: Insert each hinge blade into its respective slot in the door leaf and frame, securing preliminarily with the supplied stainless steel screws. Ensure all hinge bearing holes face the same direction to guarantee correct door swing. Begin fitting from the top hinge and work progressively downward for easier fine-tuning.

4. Door Hanging and Adjustment: Lift the door leaf to align the hinge plates on the door with those on the frame, then insert the hinge pins. Insert the top pin first, followed sequentially by the middle and bottom pins. Verify the door leaf is vertical and operates smoothly. Make fine adjustments by tightening or loosening the adjustment screws as required until optimal performance is achieved.

5. Final Inspection and Testing: Upon completion, conduct comprehensive functional testing. Open and close the door multiple times to check for unusual noises or sticking. Confirm the door remains stable in all positions without self-opening or closing. Finally, verify all screws are securely fastened and advise the user to perform regular inspections and maintenance to ensure this UL Door Hinge consistently delivers optimal performance.

E-mail: jobby@dndhardware.com

ADD: 12th Floor, Building 2, No.898, KeChuang Technical Zone, Jiangmen Avenue, Pengjiang District, Jiangmen City, Guangdong, China (Postcode:529000)

Https://www.dndhardware.comE-mail: jobby@dndhardware.com

ADD: 12th Floor, Building 2, No.898, KeChuang Technical Zone, Jiangmen Avenue, Pengjiang District, Jiangmen City, Guangdong, China (Postcode:529000)

Https://www.dndhardware.com