DDSH004

D&D Hardware

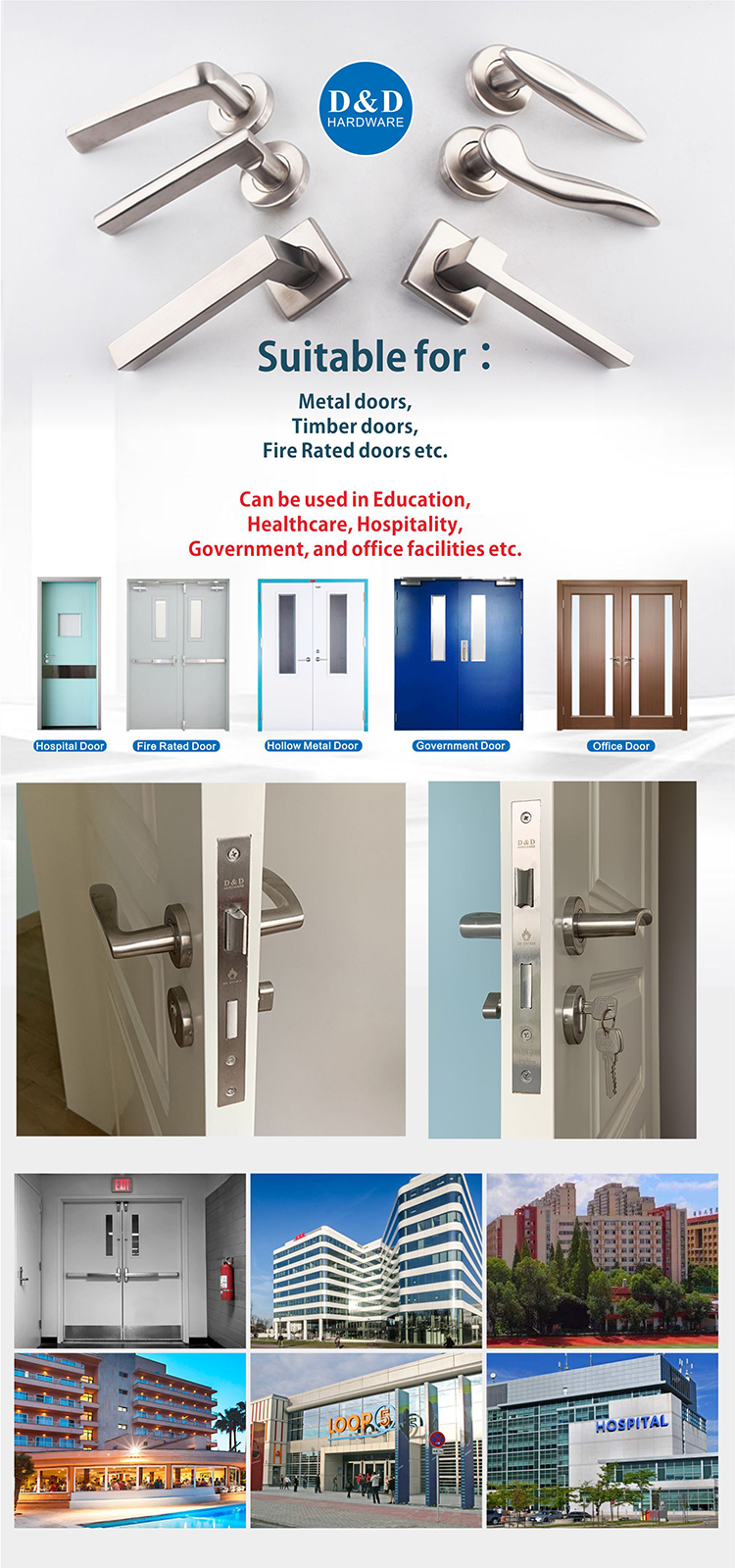

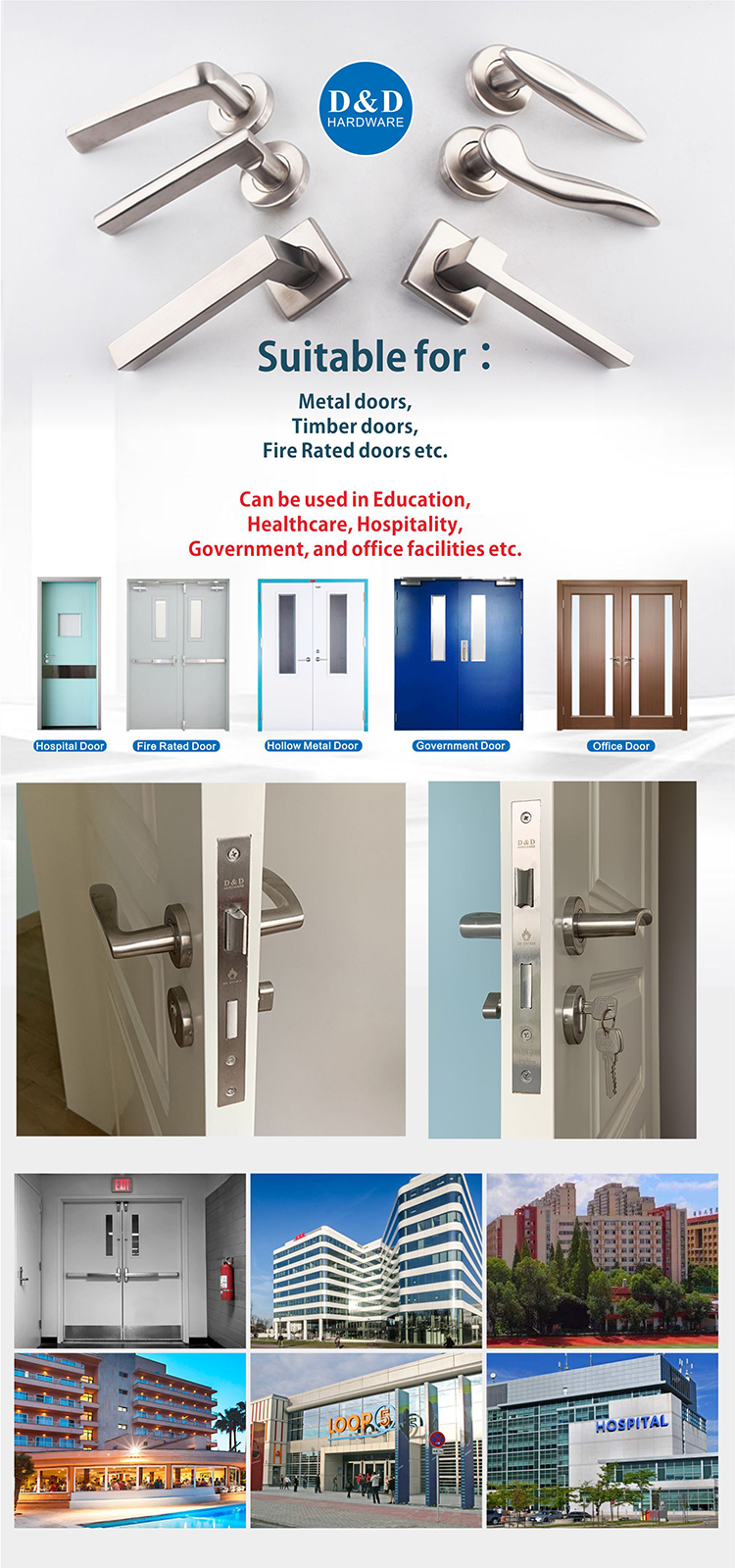

Wooden Door, Metal Door, Steel Door, Interior Door, Outer Door

Stainless Steel

SSS , PSS , PVD , PB, AB , AC , MB

T/T, L/C, D/P, Western Union

Jiangmen /Guangzhou / Shenzhen , China

200,000/Month

| Availability: | |

|---|---|

| Quantity: | |

The solid stainless steel door handle is engineered for commercial-grade performance, offering stable mechanical function, durable construction, and precise manufacturing quality. Although this model is not certified under EN1906, it is manufactured in accordance with the structural requirements and performance guidelines defined in the EN1906 standard to ensure reliable operation in high-traffic environments. For further information, please contact us.

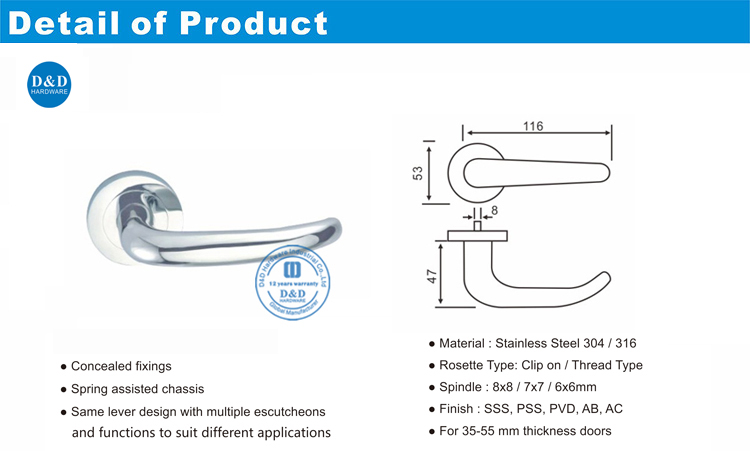

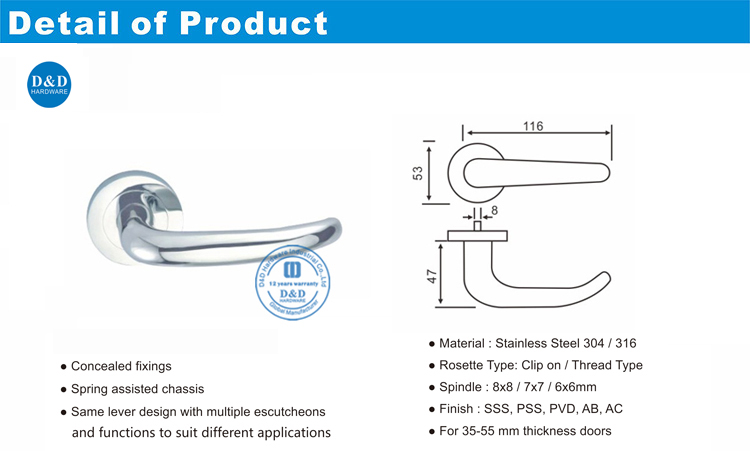

| Product name | Modern Door Handles Stainless Steel Interior Door Solid Lever Handle-DDSH004 |

| Product Model | DDSH004 |

| Size | L116mm x W47mm |

| Diameter | Φ16 / Φ19 / Φ20 / Φ22 |

| Feature | Concealed fixings, Spring assisted chassis, Same lever design with multiple escutcheons and functions to suit different applications |

| Material | Stainless steel |

| Finish | Satin stainless steel, Polished stainless steel, Physical Vapor Deposition ,Antique Brass, Antique Copper ,Matte Black ,Polished Brass |

| Inner Rose | Steel or Stainless steel |

| Outer Escutcheon | Stainless steel |

Accessories | Brass insert, rosette with base , escutcheon with base, spindle, wooden screws, bamboo screws , allen key |

Suitable for | Wooden door, Metal door, Steel door etc. |

| MOQ | 200 sets |

| Package | 1 set per inner box and 20 sets per outer double corrugated carton. |

| Sample time | 5-7 working days |

| Production lead time | 30-35 days normally |

| Shipping Port | Jiangmen , China / Shenzhen , China . |

The solid stainless steel door handle is engineered for commercial-grade performance, offering stable mechanical function, durable construction, and precise manufacturing quality. Although this model is not certified under EN1906, it is manufactured in accordance with the structural requirements and performance guidelines defined in the EN1906 standard to ensure reliable operation in high-traffic environments. For further information, please contact us.

| Product name | Modern Door Handles Stainless Steel Interior Door Solid Lever Handle-DDSH004 |

| Product Model | DDSH004 |

| Size | L116mm x W47mm |

| Diameter | Φ16 / Φ19 / Φ20 / Φ22 |

| Feature | Concealed fixings, Spring assisted chassis, Same lever design with multiple escutcheons and functions to suit different applications |

| Material | Stainless steel |

| Finish | Satin stainless steel, Polished stainless steel, Physical Vapor Deposition ,Antique Brass, Antique Copper ,Matte Black ,Polished Brass |

| Inner Rose | Steel or Stainless steel |

| Outer Escutcheon | Stainless steel |

Accessories | Brass insert, rosette with base , escutcheon with base, spindle, wooden screws, bamboo screws , allen key |

Suitable for | Wooden door, Metal door, Steel door etc. |

| MOQ | 200 sets |

| Package | 1 set per inner box and 20 sets per outer double corrugated carton. |

| Sample time | 5-7 working days |

| Production lead time | 30-35 days normally |

| Shipping Port | Jiangmen , China / Shenzhen , China . |

The handle is produced from solid SUS304 or SUS316 stainless steel, depending on the configuration. These materials are selected for their high tensile strength, corrosion resistance, and long-term surface stability, making the handle suitable for demanding commercial applications. The solid construction provides superior rigidity compared to hollow designs, reducing material fatigue and improving resistance to continuous mechanical stress.

During production, the internal spindle, fixing mechanism, and spring system are precision-machined to ensure smooth lever rotation and consistent return action. The spring cassette is designed with a reinforced dual-spring configuration, which enhances durability and maintains reliable performance even after extended use. This mechanism helps minimize looseness or handle sagging over time, a critical factor in maintaining operational quality in commercial door systems.

The door handle is manufactured following EN1906 structural categories, including lever strength, torque resistance, durability cycles, and corrosion resistance guidelines. While not third-party certified, internal tests replicate key aspects of EN1906 performance expectations:

-Cycle Test: Mechanical endurance testing exceeding 200,000 operating cycles

-Torque Resistance Test: Ensuring structural stability under rotational stress

-Impact Resistance: Evaluating handle performance under repeated mechanical loading

-Corrosion Resistance Test: Salt-spray exposure based on standard testing durations

These internal laboratory tests verify that the product meets the functional requirements expected of commercial-grade handle systems.

The handle’s surface finishing is processed using multi-stage polishing and passivation treatment to improve corrosion resistance and long-term appearance. Optional surface finishes include satin, mirror, PVD, and custom coatings, each tested for surface hardness and abrasion resistance.

Engineering dimensional accuracy is maintained through CNC machining, ensuring tight tolerances for spindle fitment, rose or plate alignment, and screw fixing points. This level of precision allows the handle to integrate seamlessly with various commercial lock cases and door systems while maintaining stable performance.

For installation, the handle supports door thicknesses ranging from 35 mm to 55 mm, with compatibility for both wooden and metal commercial doors. The fixing structure uses solid through-bolts to ensure a secure and vibration-resistant attachment. This installation method enhances long-term stability, making the product suitable for heavy-duty environments.

Quality control includes raw material verification, dimensional inspection, mechanical performance testing, and final assembly checks. Each batch is monitored for consistency in operation, handle torque, and surface quality to maintain dependable engineering standards.

This solid stainless steel door handle offers engineering-grade durability, precise construction, and stable mechanical functionality, making it a reliable option for commercial projects that require high-quality hardware manufactured in accordance with established industry standards.

The handle is produced from solid SUS304 or SUS316 stainless steel, depending on the configuration. These materials are selected for their high tensile strength, corrosion resistance, and long-term surface stability, making the handle suitable for demanding commercial applications. The solid construction provides superior rigidity compared to hollow designs, reducing material fatigue and improving resistance to continuous mechanical stress.

During production, the internal spindle, fixing mechanism, and spring system are precision-machined to ensure smooth lever rotation and consistent return action. The spring cassette is designed with a reinforced dual-spring configuration, which enhances durability and maintains reliable performance even after extended use. This mechanism helps minimize looseness or handle sagging over time, a critical factor in maintaining operational quality in commercial door systems.

The door handle is manufactured following EN1906 structural categories, including lever strength, torque resistance, durability cycles, and corrosion resistance guidelines. While not third-party certified, internal tests replicate key aspects of EN1906 performance expectations:

-Cycle Test: Mechanical endurance testing exceeding 200,000 operating cycles

-Torque Resistance Test: Ensuring structural stability under rotational stress

-Impact Resistance: Evaluating handle performance under repeated mechanical loading

-Corrosion Resistance Test: Salt-spray exposure based on standard testing durations

These internal laboratory tests verify that the product meets the functional requirements expected of commercial-grade handle systems.

The handle’s surface finishing is processed using multi-stage polishing and passivation treatment to improve corrosion resistance and long-term appearance. Optional surface finishes include satin, mirror, PVD, and custom coatings, each tested for surface hardness and abrasion resistance.

Engineering dimensional accuracy is maintained through CNC machining, ensuring tight tolerances for spindle fitment, rose or plate alignment, and screw fixing points. This level of precision allows the handle to integrate seamlessly with various commercial lock cases and door systems while maintaining stable performance.

For installation, the handle supports door thicknesses ranging from 35 mm to 55 mm, with compatibility for both wooden and metal commercial doors. The fixing structure uses solid through-bolts to ensure a secure and vibration-resistant attachment. This installation method enhances long-term stability, making the product suitable for heavy-duty environments.

Quality control includes raw material verification, dimensional inspection, mechanical performance testing, and final assembly checks. Each batch is monitored for consistency in operation, handle torque, and surface quality to maintain dependable engineering standards.

This solid stainless steel door handle offers engineering-grade durability, precise construction, and stable mechanical functionality, making it a reliable option for commercial projects that require high-quality hardware manufactured in accordance with established industry standards.

Address: 12th Floor, Building 2, No.898, KeChuang Technical Zone,Jiangmen Avenue, Pengjiang District, Jiangmen City, Guangdong, China (Postcode:529000)

Https://www.dndhardware.comAddress: 12th Floor, Building 2, No.898, KeChuang Technical Zone,Jiangmen Avenue, Pengjiang District, Jiangmen City, Guangdong, China (Postcode:529000)

Https://www.dndhardware.com