Views: 0 Author: D&D Hardware Publish Time: 2021-02-06 Origin: D&D Hardware

Surface mounted door closers

Surface mounted door closers are the most efficient and economical means of controlling doors and are thus, the most commonly used type of closers. But, because they are exposed to view, there are some installations where a concealed door closer better suits the needs of the owners and users.

On exterior openings, surface door closers should always be installed on the interior side of the openings to protect the closers from fluctuations in temperature.

On interior openings, good practice dictates that surface door closers be installed on the room side of the openings, out of the corridor.

Mounting a Door Closer:

Door closers may be mounted on either the pull side (hinge side) or push side of the door. In either case, door closers should always be mounted on the inside of a building (out of the weather) and usually on the inside of a room for aesthetics.

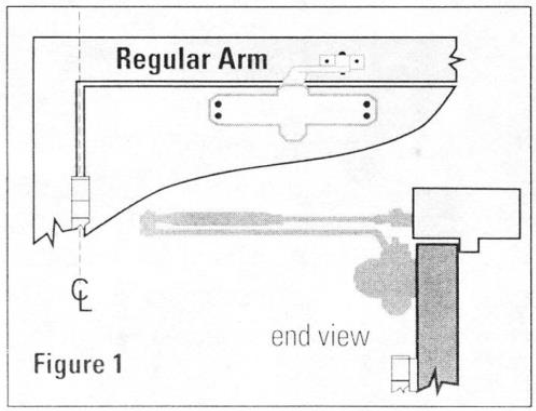

If the door opens in — into a building or room — the closer would be installed in "regular arm" application (figure 1).

Regular arm application

Regular arm door closers are used on openings where the closer needs to be installed on the pull side of the opening.

Regular arm door closers are installed with the closer body attached to the face of the door, on the pull side of the opening, and the arm is attached to the face of the frame. In cases where the door has a narrow top rail, a special adapter plate is used to attach the closer body to the door. Properly installed, the arm is place at 90 degrees perpendicular to the face of the door.

If the door opens out — to the outside of a building or room — one of three applications may be selected. Use Parallel arm, Top Jamb or Corner Bracket closers.

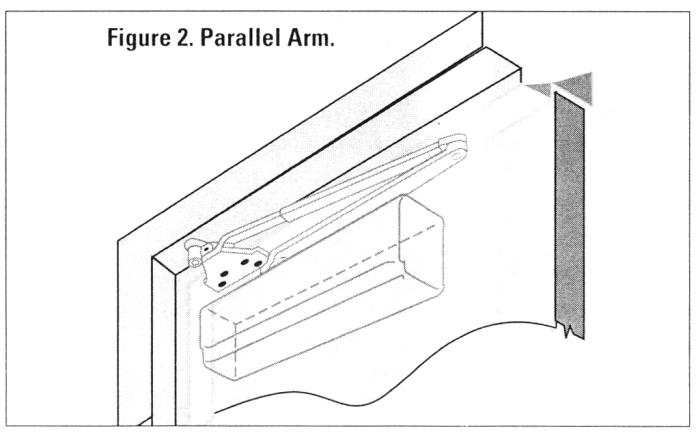

1. Parallel arm application

Parallel arm door closers are used on openings where the closer needs to be installed on the push side of the opening. Typically, a parallel arm closer requires the door to have a top rail approximately 5-1/2 inches in height.

Parallel arm door closers are installed with the closer body attached to the face of the door, on the push side of the opening, and the arm is attached to the soffit of the frame. Adapter plates are used to attach the closer body to doors with narrow top rails.

This application can help prevent vandalism since the arm is protected under the door frame. It is less likely that someone would reach up and pull down on the arm. This application (figure 2) is very common in schools. Since the arm is parallel to the door, power efficiency is reduced: Power is 25 percent less than regular arm application.

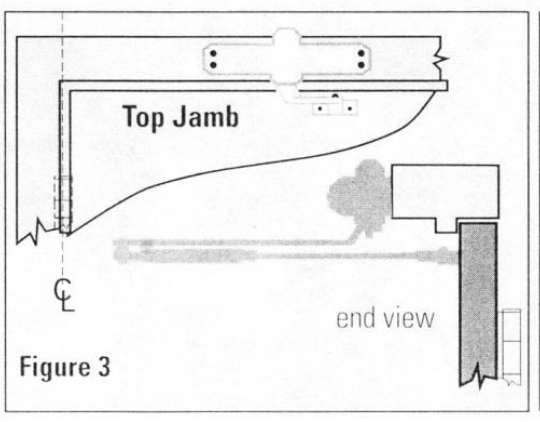

2. Top jamb application

Top jamb door closers are frequently used on openings where the door has a narrow top rail and the closer needs to be installed on the push side of the opening. Installing a closer in this manner keeps the closer body out of the glazed area of the door, making it a more aesthetically appealing application.

Top jamb door closers are installed with the closer body attached to the face of the frame on the push side of the opening and the arm attached to the face of the door. Properly installed, the arm of the closer is placed at 90 degrees perpendicular to the face of the door.

This application is very common on aluminum glass doors, such as those used on storefronts (figure 3). The 1 11/16" flat frame face allows easy installation of the door closer body while the limited space on the top rail of the door still allows for the attachment of the arm. This application also allows for good power efficiency. Power efficiency is very important on exterior outswing doors that open past 110°.

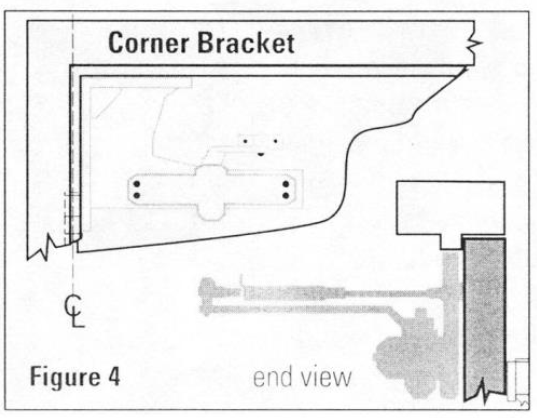

3. Corner bracket application

Corner brackets are sometimes used to install surface door closers on openings that have a door with an angled or arched top rail.

The corner bracket is installed on the push side of the opening and attached to the soffit of the hinge jamb of the frame. The closer body is mounted to the bracket and the arm is attached to the face of the door.

Corner brackets, once a common method of installing traditional style door closers, are used less often today. One disadvantage of corner bracket installations is that the bracket and closer project into the clear width of the opening when the door is in the open position and could cause problems with headroom clearance.

This application is more commonly found in older buildings where the traditional or "pot" type door closer may have been installed (figure 4). Corner brackets were originally developed as the only alternative to installing the door closer on the push side of the door. Because of improvements made to modern day door closers, which are generally installed either parallel arm or top jamb, the use of the corner bracket application has been virtually eliminated.

Although some door closer manufacturers still offer corner brackets, this application should be used with caution. The bracket drops down into the opening approximately 8", which seriously reduces head room clearance. For this reason, the corner bracket application is often referred to as a "head knocker."

Door closer features may be standard or optional depending on the closer selected. Optional features must be specified when ordering the closer and are added to the basic price of the closer.

Here’s a corner bracket for reference only

Fire-rated doors must be equipped with a self-closing or automatic-closing device to ensure the door is keep in the closed and latched position. Standard UL door closers supplied by D&D have passed below standard:

- UL 228, Door Closers –Holders, With or Without Integral Smoke Detectors

- CAN/ULC-S133-07, Door Closers Intended for Use With Swinging Doors

- UL 10 C,Standard for Safety for Positive Pressure Fire Tests of Door Assemblies

And we offer a 5 year Mechanical Guarantee for our certified product, D&D is your reliable supplier.

For further information about door closers or any of our services, click here.

Contact us Now:

Contact: David Jian

Mob: 0086-139 2903 7292

Email: David@dndhardware.com, sales@dndhardware.com

Jobby Zhang

Mob: 0086-137 2599 9617

Email: jobby@dndhardware.com

: +86-139 2903 7292

: +86-139 2903 7292